Metalworking is the process of working with metals to create individual parts, assemblies, or large-scale structures. Aside from hand tools, machine tools are also used during metalworking. There are specific machines used in metal workshop. They make work faster and easier.

Types of metal work machines

They include:

1. The lathe machine

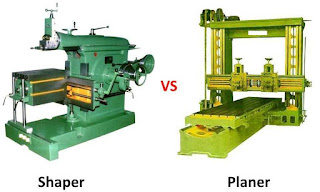

2. Shapers and planers

3. Milling machine

4. Grinding machine and

5. The drill press

Functions of metal work machines

The lathe is a machine that shapes pieces of metal by holding and turning them against a fixed cutting tool. Screw cutting is done on the lathe.

|

| Lathe |

Shapers and planers are used for shaping and smoothing and for making rough surfaces smooth

The milling machine allows several cutting operations to be carried out such as the cutting of gears and slots in large quantities.

|

| milling machine |

The grinding machine is used to sharpen metal cutting tools like drill, cold chisel, lathe and shaper tools when they become blunt due to prolonged use.

|

| grinding machine |

The drill press is a machine that can hold the drills and turn in order to drill a hole in metal or other materials.

|

| drill press |

i like your blog. Its very useful for teachers and educators

ReplyDeleteIn building our homes metal is required. These days, the most recent pattern of material is made of metal. Metal material offers quality, adaptability and changelessness to compliment any home structure.best laser cutting machine

ReplyDeleteThe method of metal casting includes melting of metals with the high temperature and by utilization of molds to shape metals into a new item. microfusione

ReplyDelete